| ||

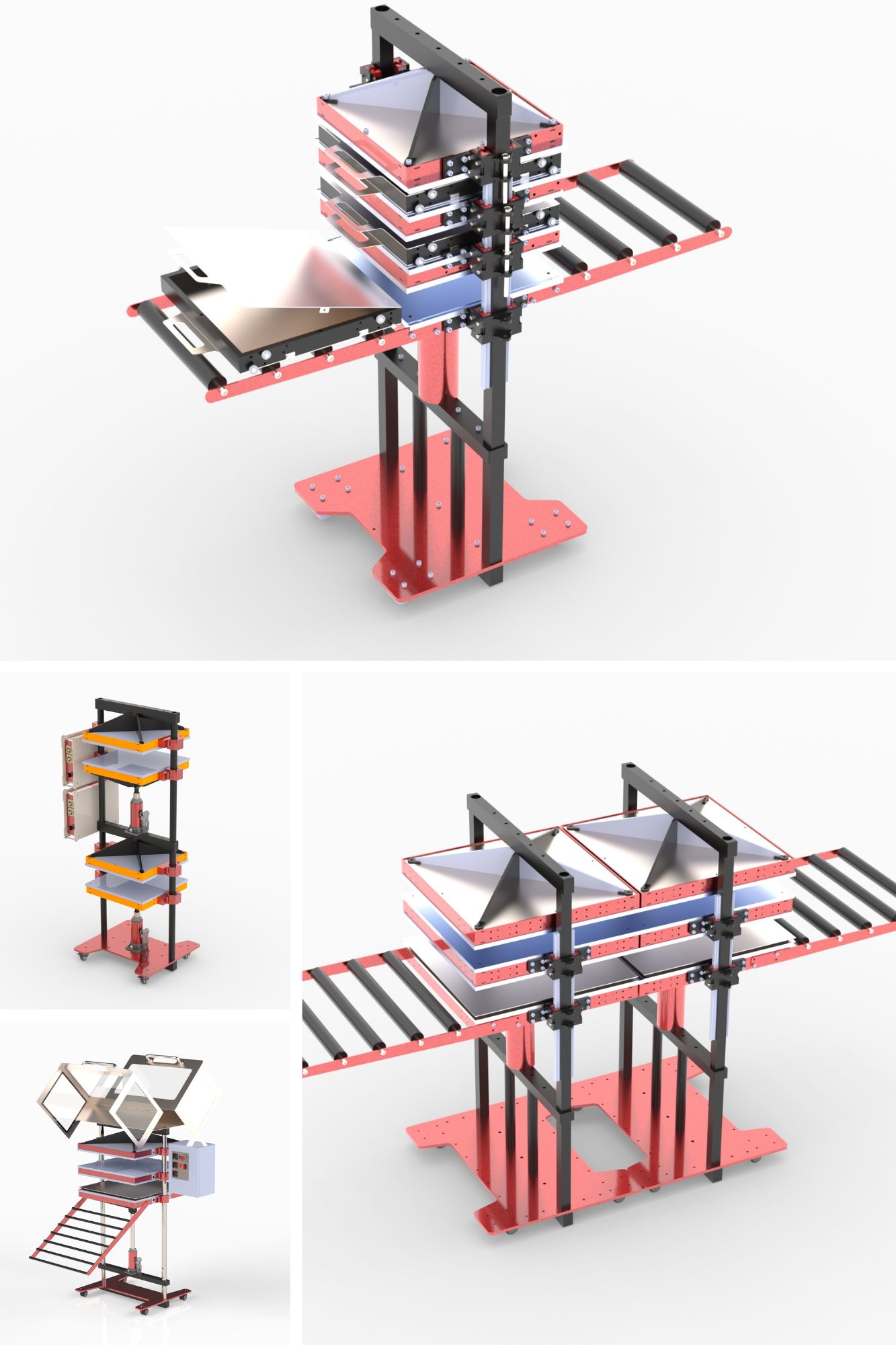

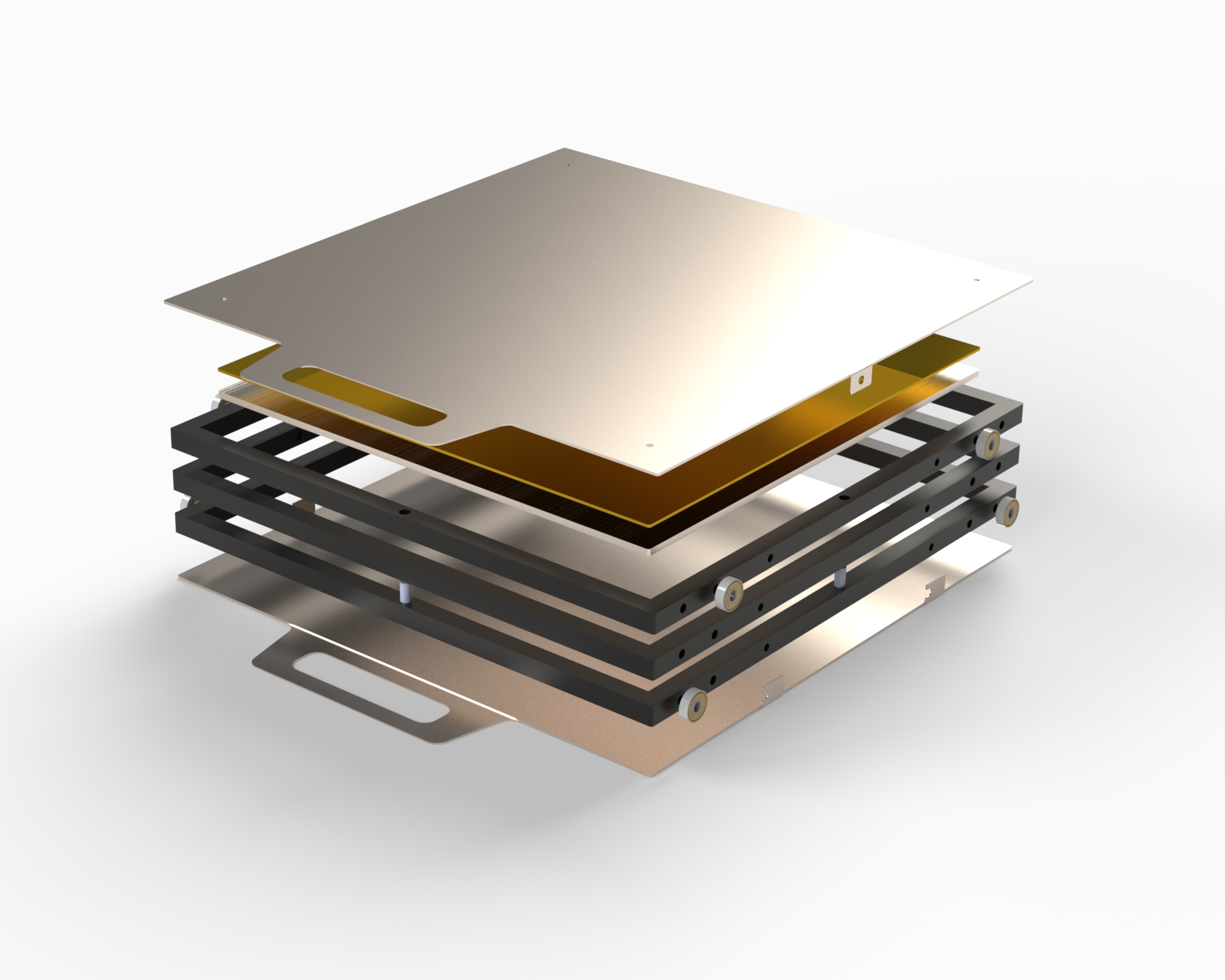

Our latest sheetpress designs, optimized for safety, flexibility, compactness, modularity, and accessibility, ensuring a smooth and clean process for small enterprises and educational settings. Cassandra - 45 cmWe recommend this version for Fablabs, schools and research institutions for its maximized safety. As all variants, the press can be configured for up to 4 individual heat and/or cooling zones. A fully maxed out mould weights up to 18kg. Cassandra - 65 cmThis variant is optimized for production scenarios, enabling an interlocked setup for 1.2m x 60cm sheets. A fully maxed out mould weights from 22kg to 40kg. Cassandra - 110 cmThis variant is optimized for production scenarios currently under development. MouldsWe introduced a new mould design that allows for a clean, safe and repeatable process. The mould is height adjustable and rollers prevent damage of the heat press plate but also position the mould inside the sheetpress precisely. Furthermore the outer protection sheets snap onto the mould frame to avoid plastic from falling out. No mould release agent is needed. Clients

Coming up next

Resources | ||

|