| .. | ||

| 20230315_152528-18a5f104891.jpg | ||

| 20230315_152528-18a5122f2a3.jpg | ||

| 20230623_113418-18a5121aac5.jpg | ||

| 20230711_120925-18a512093f5.jpg | ||

| 20230831_114152-18a511c7317.jpg | ||

| 20230831_114209-18a511c83b3.jpg | ||

| 20230831_114253-18a511c8ea3.jpg | ||

| 20230831_115246-18a5122e6d1.jpg | ||

| config.json | ||

| index.astro | ||

| index.mdx | ||

| README.md | ||

| references.md | ||

| resources.md | ||

| Screenshot_20230830_124924_Gallery-18a5119b7de.jpg | ||

| Screenshot_20230901_160800_Gallery-18a51219968.jpg | ||

| title | slug | description | tags | category | difficulty | time | keywords | location | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Make a stool with upcycled PETG 3D print waste | make-a-stool-with-upcycled-petg-3d-print-waste | In this How-To we'll teach you how to transform 3D print waste in design objects, using a shredder, a sheetpress and a CNC |

|

uncategorized | Medium | < 1 day | Calenzano, Italy |

Make a stool with upcycled PETG 3D print waste

In this How-To we'll teach you how to transform 3D print waste in design objects, using a shredder, a sheetpress and a CNC

In this How-To we'll teach you how to transform 3D print waste in design objects, using a shredder, a sheetpress and a CNC

User Location: Calenzano, Italy

Steps

Step 1: Collect plastic

First of all you have to collects all the plastic waste that came from your 3D print like supports or corrupted prints Divide it in type of plastic like PLA, PETG, ABS etc...

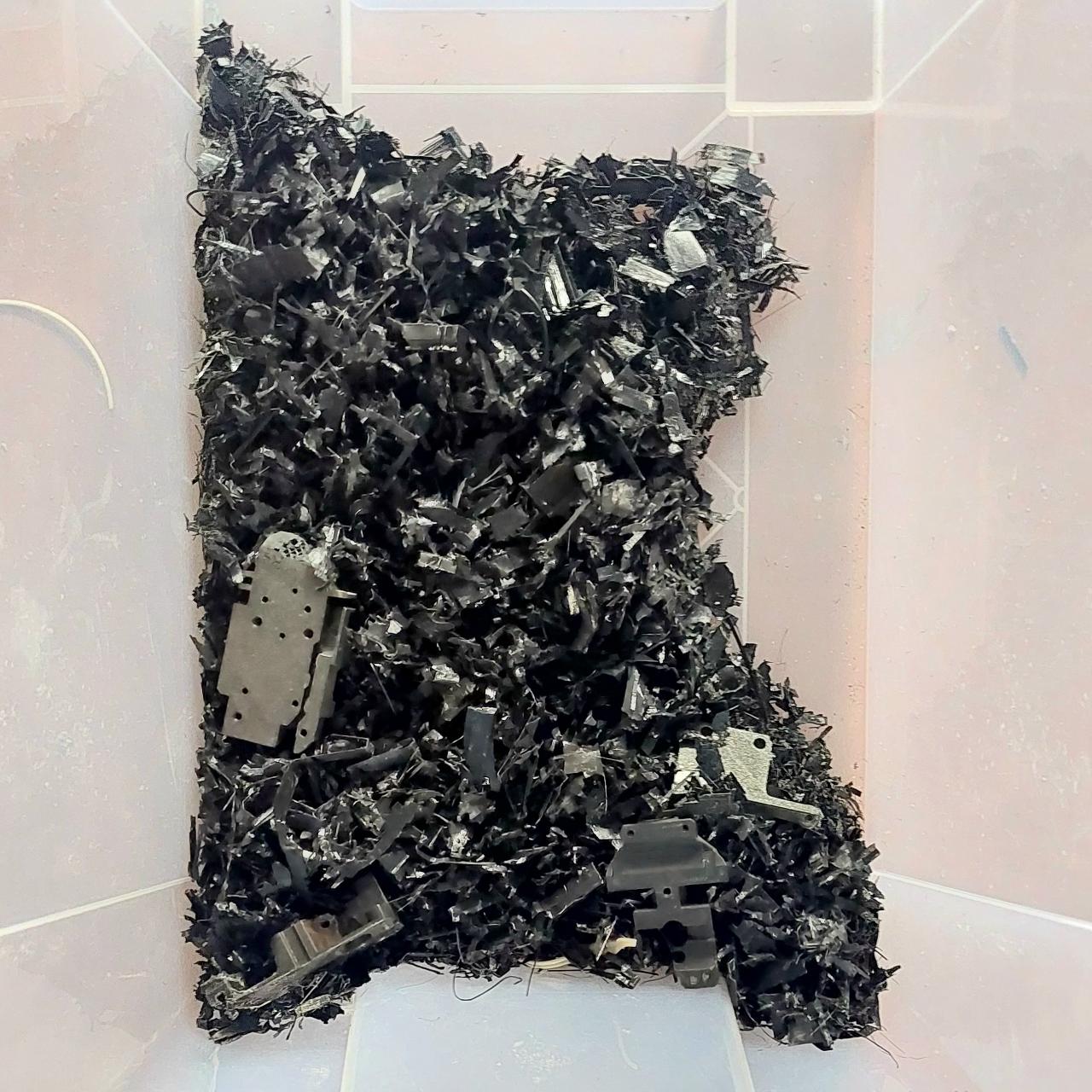

Step 2: Begin to shredd

At this point you have to shred the material and collect it. Decide how many times to pass it from the shredder according to the size you want to collect

Step 3: Now it's time for the sheetpress

Now we place all our chopped plastic in the 1X1MT mold, we put it into the sheetpress and we create our upcycled plastic sheet

Step 4: Time for the CNC

Now we put our 1X1MT sheet, cutted in 35X35CM pieces under the CNC and we create rouded pieces with a diameter of 30CM

Step 5: Work is done

Now all that remains is to drill the recycled plastic discs to be fixed to a metal base, and here is our stool