| .. | ||

| 1.jpg | ||

| 2.jpg | ||

| 3.jpg | ||

| 4.jpg | ||

| 5.jpg | ||

| 6.jpg | ||

| 7.jpg | ||

| 8.jpg | ||

| 9.jpg | ||

| 10.jpg | ||

| config.json | ||

| index.mdx | ||

| README.md | ||

| references.md | ||

| resources.md | ||

| title | slug | description | tags | category | difficulty | time | keywords | location | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Stamp products fast. Without heating | stamp-products-fast-without-heating | We will show you how you can stamp the products you made in a fast efficient way. The main benefit is that it doesn’t require heating so you have no heatup/cooldown times. This is good for bigger productions and just saves energy :) |

|

Guides | Easy | < 1 week | Chennai, India |

Stamp products fast. Without heating

We will show you how you can stamp the products you made in a fast efficient way. The main benefit is that it doesn’t require heating so you have no heatup/cooldown times. This is good for bigger productions and just saves energy :)

We will show you how you can stamp the products you made in a fast efficient way. The main benefit is that it doesn’t require heating so you have no heatup/cooldown times. This is good for bigger productions and just saves energy :)

User Location: Chennai, India

Steps

Step 1: Get a product

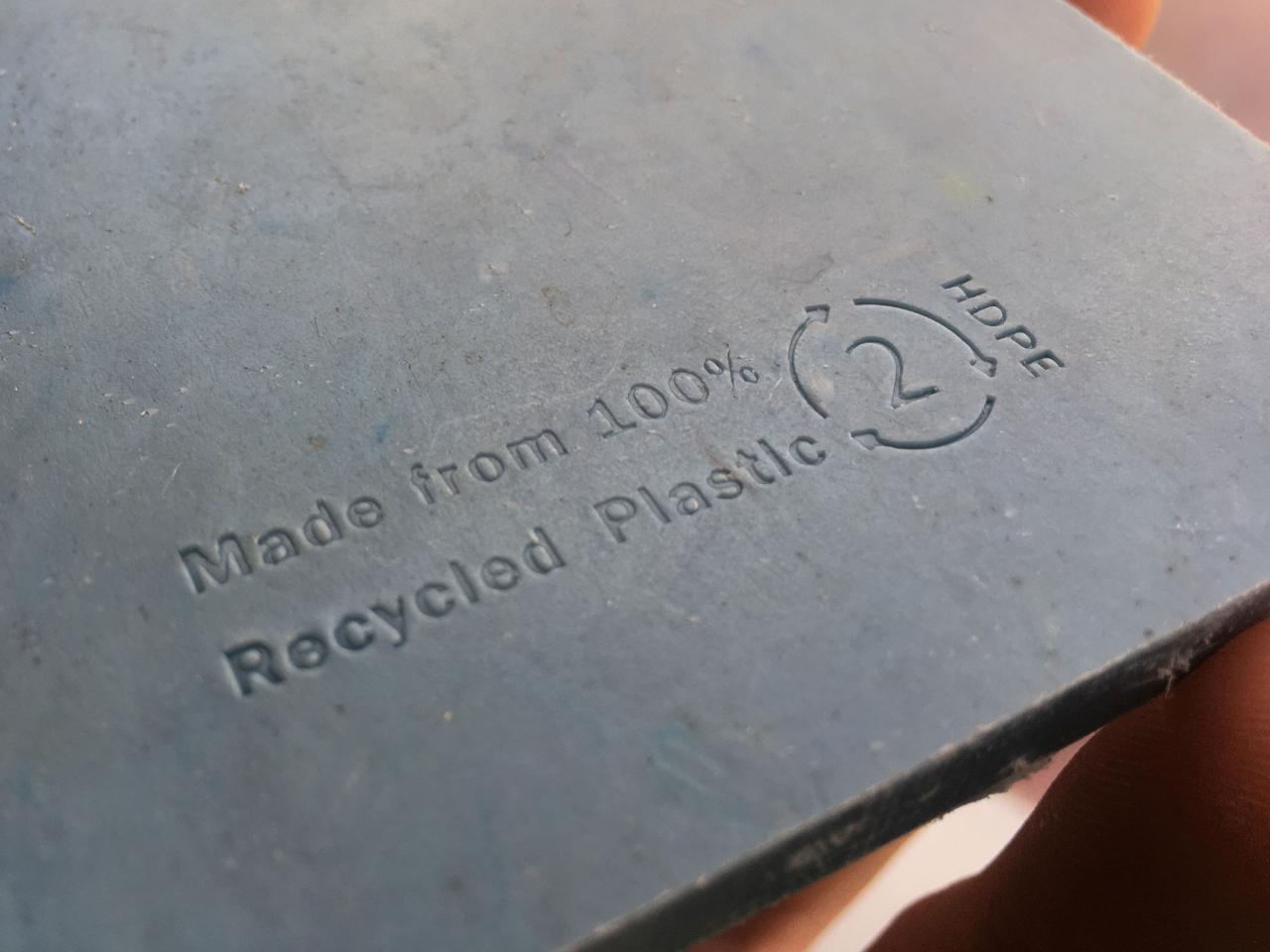

First you need to have a product. We work with sheets and cut them with CNC to make products. We only tried this technique with PP and HDPE. So let’s met show you how we stamp them.

Step 2: Make your stamp

Make a design for your stamp and mill it in metal. We made ours from brass, but I guess other metals would work as well. Tip: make sure to mirror your design

Step 3: Press

For pressing we like to use arbor press. It works fast and are easy to use/find. Put the product underneath apply some fore and take it out. You can get really fast here

Step 4: Use mould for alignment

We like it when things are consistent. So we use a little mould to put in our product to make sure we always stamp in the same place. This actually also makes sure the product doesn’t move when applying force. Not a must, but would highly recommend

Step 5: Ready!

Here you can see a few products we stamped. We made one stamp for our logo and one for the type of plastic. Have fun making yours! :)