7.2 KiB

Overview

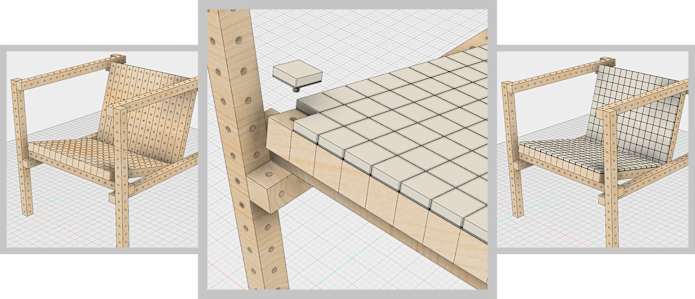

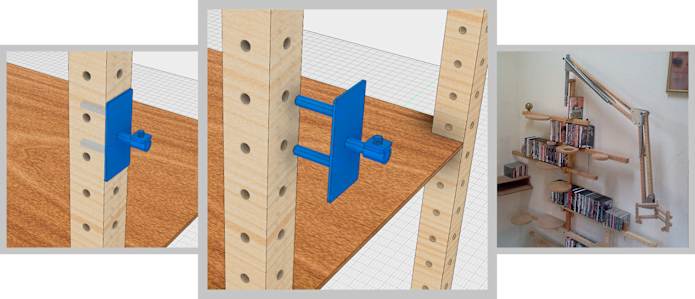

BeamCNC is a tool for production modular construction system and a part of the equation for creating globally distributed manufacturing network for Grid Beam like construction system!

Short history of Grid Beam

Early version of this construction system was developed by Ken Isaac in the late 1940s. He used 2x2 lumber and three dimentional joints to create living structures. He called this construction system - Matrix and later publish a book How to Build Your Own Living Structures. After this book a group of artists, designers and builders continued to work on developing this construction system. They upgraded and standardized it, made it fully modular. Three of them later summarized their work in a book How to Build with Grid Beam: A Fast, Easy and Affordable System for Constructing Almost Anything. And I`ve learned about Grid Beam from Kevin Kelly Cool Tools blog (which is also awesome, you should check it out).

Gallery of examples

BeamCNC features

(this is a prototype. backers will receive v1.0 with more features listed below)

- works with lumber or aluminum square tube

- X form factor compensates material size variations and small curvature that off the shelf lumber often has

- suitable for beams from 20mm up to 50mm (from 3/4 to 2 inches) of any length

- drilling pattern set by gcode file (you can generate your own patterns)

- portable (manufacture construstion system onsite)

- almost dustless operation (home friendly)

Things I will upgrade in v1.0 before shipping it to backers:

- wire management

- sturdier frame

- whole length (drilling near the ends of the lumber)

- better dust collecton (it is almost dustless with current dust collection design, but I want to make usability a bit easier)

- smaller footprint

- optimized working speed

- perpendicular hole alignment

- beam leveling

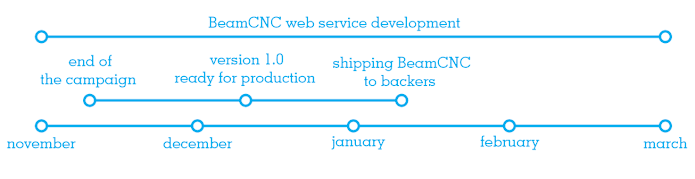

Timeline

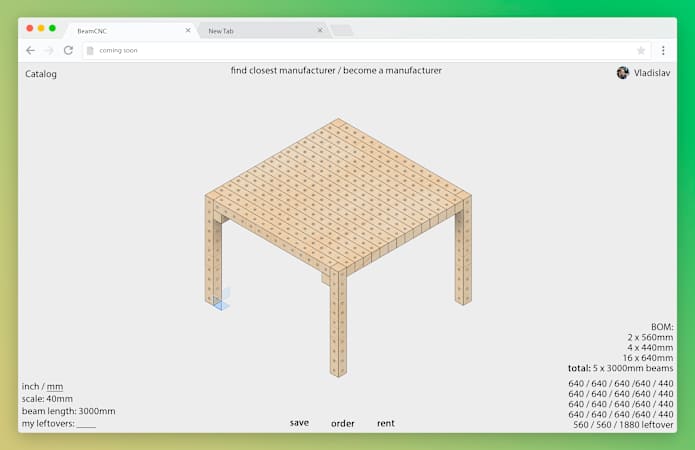

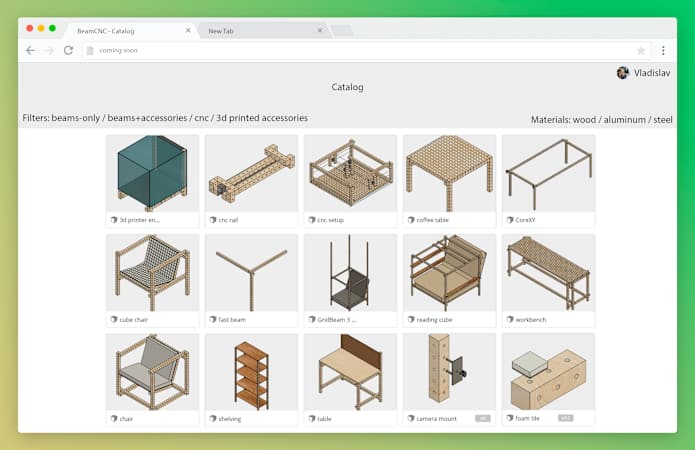

Web service

You will be able to mockup designs from grid beam. Share your designs and explore what other people have designed. Get best spliting setup for a project to minimize leftovers. Generate custom gcode files. Find or become a local manufacturer. Every backer who has bought an original BeamCNC will automatically get an autorisation code for becoming a local manufacturer. It`s up to you to decide whether to use BeamCNC for yourself or introduce yourself as a local manufacturer.

While web is under development I`m starting a Facebook page for people to share thier ideas. And you can download a template file for mockups in Fusion 360 (copy-paste beams of needed length for your design. By default they are hidden, so you can`t see them on preview)

Ideas

3d printed tile with foam.

Quick camera mount on any grid beam surface. Or even whole camera arm.

Linear actuators and CNC are one of the interesting cases. You can set hole sizes to fit linear rails and with a couple of brackets make low-precision CNC setups. Also, if you glue up grid beams at bottom and cover holes on one side you can get a nice vacuum table.

Workbench, clamping table, sanding/vacuum table (as described in previous example).

BeamCNC Plasma (with plasma torch and horizontal axis instead of router). On the photo below is LifeTrac project by OpenSourceEcology and rough sketch of the design. If you are particularly interested in this version, please fill up this form. Coming soon.

Fastbeam variation. You can drill one side with a smaller drill bit and then thread it. I guess it will be one of the fastest construction systems that way. Video about how strong are threads in wood. And DIY wooden thread taps from Matthias Wandel.

You can use BeamCNC with forstner bit or use a template for forstner bit afterwards.

Open Source

All design files will be released after campaign ends. If you are particularly interested in this, please fill up this form.

We see how digital fabrication tools affects production of the goods. We can spot a pattern. Broadly available materials + Broadly available tools + Open source designs + Web service for finding local manufacturers.

For example: Plywood + CNC router + Open sourсe designs + Web-service to find local manufacturer (like https://www.opendesk.cc/) = awesome plywood furniture and projects produced locally. 3d printing filament + 3d printer + https://www.thingiverse.com/ + https://www.3dhubs.com/ = all kinds of 3d printed projects nearby.

BeamCNC can create another one of such distributed systems. Square lumber / tubes of different sizes + BeamCNC + Open source designs + Web-service for finding local manufacturers = all kinds of Grid Beam constructions and projects for makers and local communities.