4.4 KiB

Boards made from marine litter

Creation and manufacture of boards or panels using as raw material recycled polypropylene plastic and fishing nets recovered by fishermen from the coast of Spain.

Creation and manufacture of boards or panels using as raw material recycled polypropylene plastic and fishing nets recovered by fishermen from the coast of Spain.

Learn more about creation and manufacture of products with this material here https://community.preciousplastic.com/how-to/products-made-from-marine-litter

This is a project developed jointly with Vertidos Cero Association and AIMPLAS.

User Location: Gandia, Spain

Steps

Step 1: Mares Circulares

Mares Circulares is a network project launched in 2018 with a triple objective: to clean up the coasts, protected areas and seabed of Spain and Portugal, promote recycling and boost the circular economy.

We have used some 5,200 kilos of garbage caught by volunteer fishermen in their nets when the debris was floating in the water.

The non-PET plastic was then sent to the Instituto Tecnológico de Plástico (AIMPLAS), whose technology was able to transform it into usable material through various processes.

Step 2: Preparation of material

The processed marine litter and fishing nets arrive in our workshop clean and crushed, ready to be used in the heat press.

We mix it with the base material (polypropylene) taking care about the desired proportions and quantities. It depends of texture/color we look for or thickness we need.

Before take the plastic on the sheetpress we use a kind of industrial dryer to remove moisture.

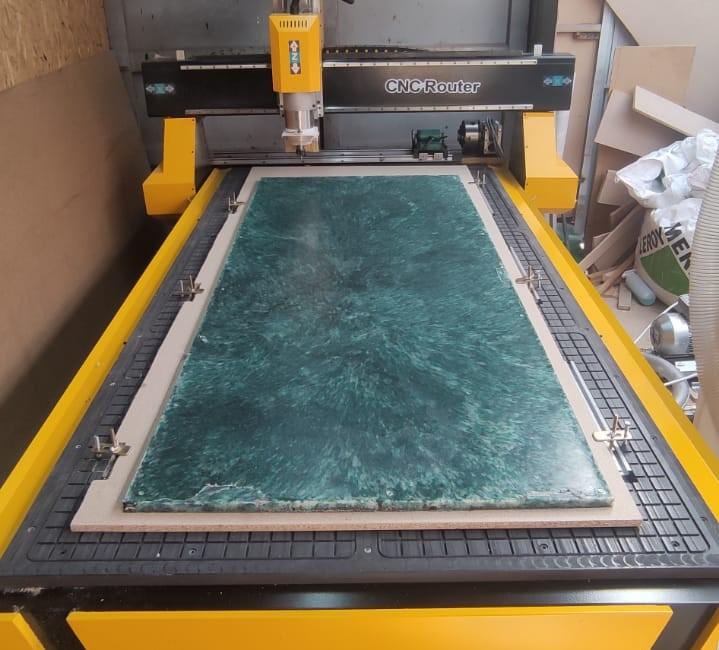

Step 3: Manufacture of boards

After having the material dry and mixed it's ready to take it to sheetpress.

Our sheetpress has been the result of our own work, we reused a carpentry press and modified to include the entire heating and automation system.

For the elaboration of boards this sheetpress allows us to manufacture boards of 220cm x 90cm and from 1cm to 3cm of thickness.

This machine reaches an average temperature of 180° centigrade to melt the plastic.

Step 4: Final details

As with any plastic processing process, the resulting parts have a surplus on the edges that has to be removed.

When we take the board out of the sheetpress we must try to have a large space to store them without deforming or bending.

With this type of boards we have the possibility to manufacture countless products, decorative, furniture and much more.